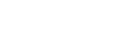

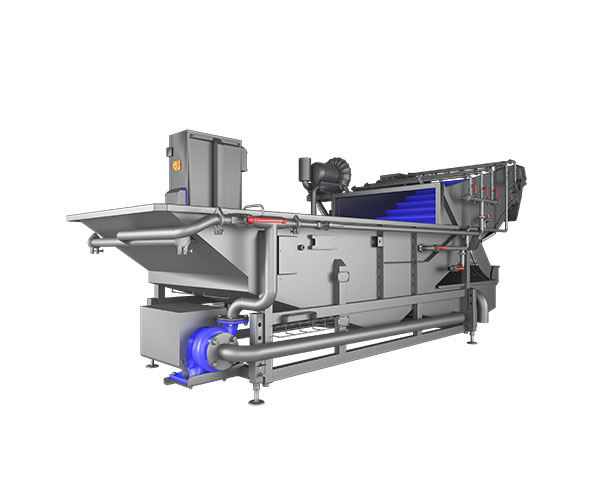

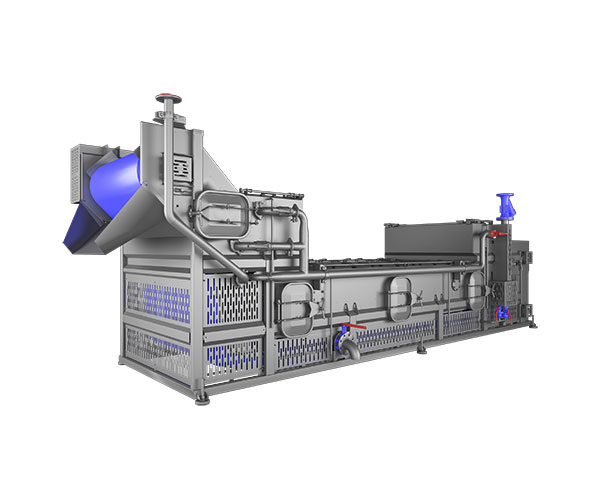

IMMERSION BELT BLANCHER

The device is designed for the heat treatment of vegetables and mushrooms before freezing or preserving them.

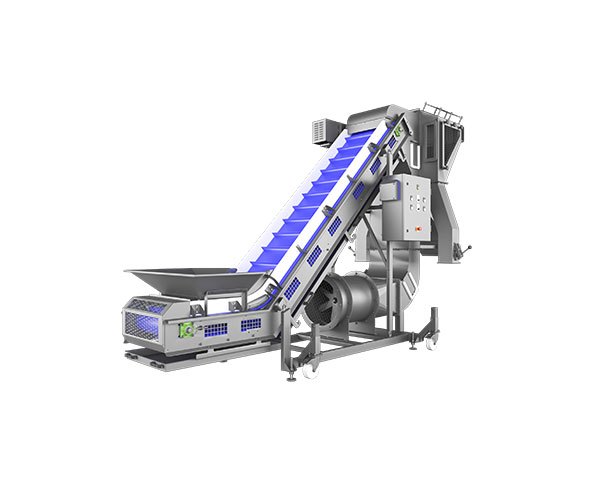

The design ensures easy maintenance of production hygiene and high work ergonomics.

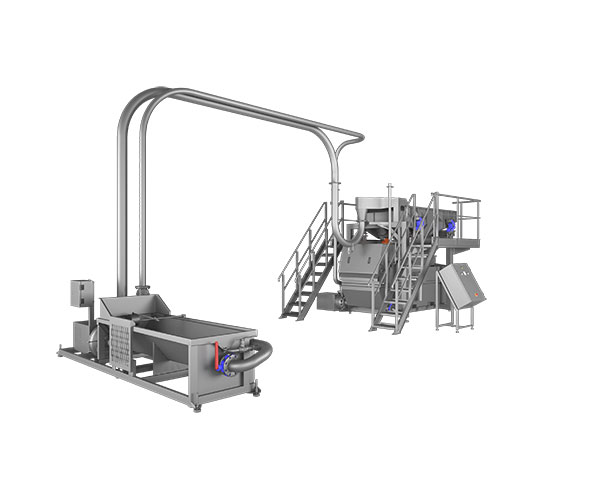

The product is put on a conveyor belt and then immersed in the water. The special design of the blancher ensures that the product is continuously submerged under water, by constantly moving it. At the end of the machine, the product, carried above the water level, passes through the cold water spray system (initial cooling and rinsing off the process water) and goes to the discharge.

The automation and control unit allows you to select the optimal process parameters (water temperature, blanching time, etc.).

Thanks to our wide range of blanchers / coolers, we can easily meet all of our customers’ requirements for blanching.

The benefits of using the device are functionality, cost-effectiveness, high performance and obtaining a product tailored to the individual needs of a client.