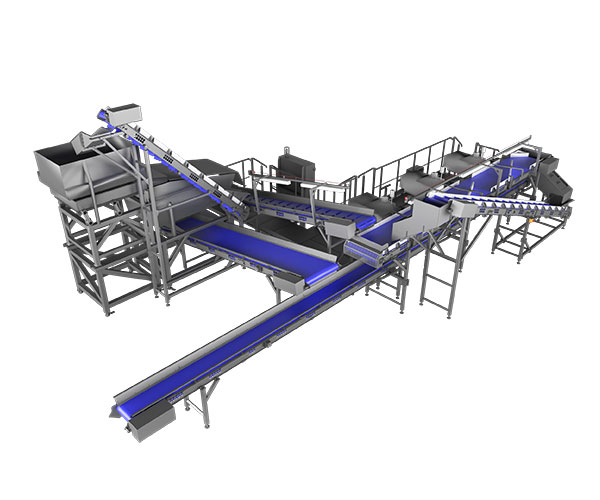

CORN LINE

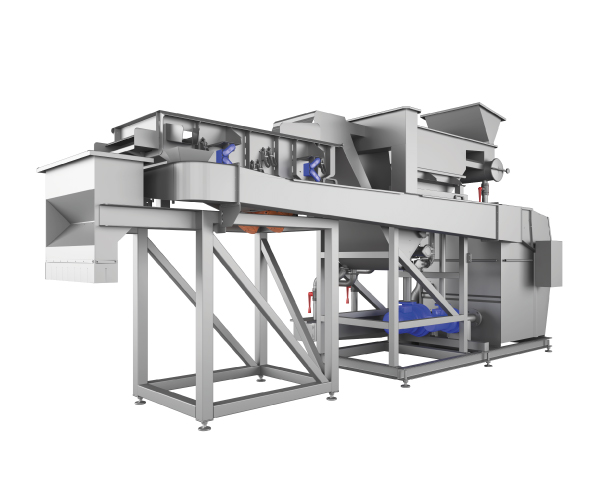

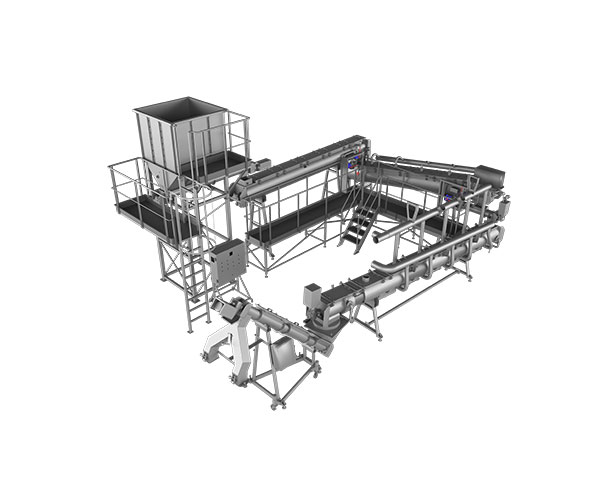

A modern, customized line that enables the processing of corn cobs into a frozen form or prepares them for packing into cans and jars and, as a whole corn cobs, into trays. All lines and machines produced by us are individually tailored to the customer’s needs.

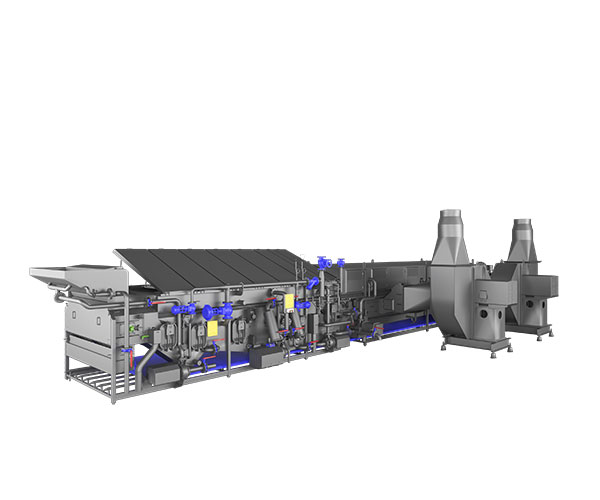

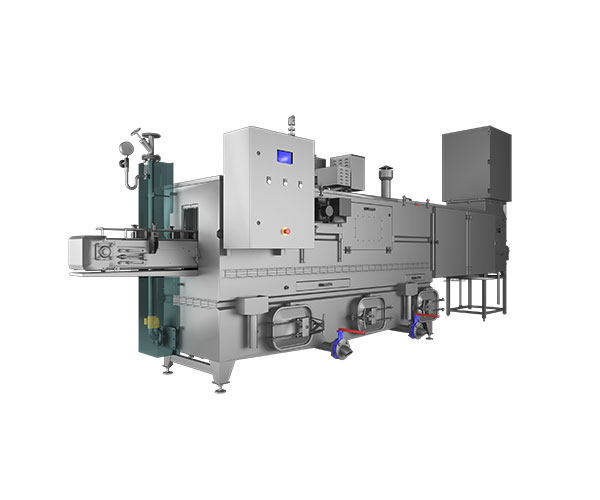

The process begins with taking whole corn cobs from the receiving hopper and steaming them, which greatly facilitates the separation of the green parts from the cob.

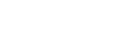

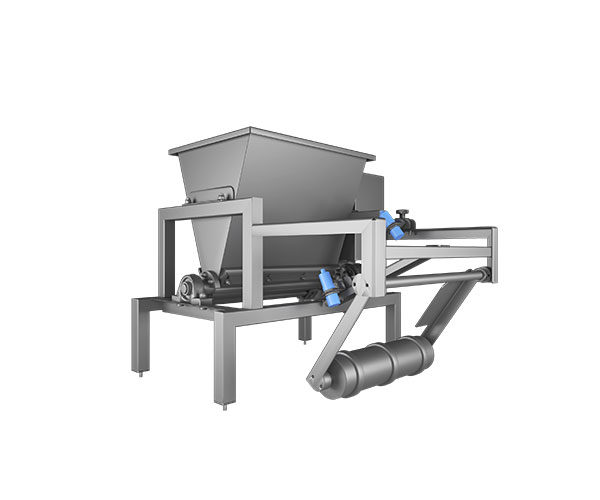

After this stage, the product is fed to the husker, which peels the cob from the green part/leaves. The process does not damage the product. The peeled cob goes to the debarker, whose task is to peel the kernels.

In order to avoid the penetration of impurities such as fibers, the line is equipped with a dirt separator, which is the next step after the debarker.

In the next step, the prepared product is washed in a flotation washer and then visually inspected. At this stage, you can integrate the line with an optical sorter.

Depending on your individual requirements for the final product, you can redirect the corn to be canned or blanched, and then to the cooling tunnel and the packing line.

Detailed refinement of this line resulted in a carefully thought-out concept of the technological process and transparent operation of the devices. Thanks to the cooperation with our clients, we can learn more about their needs and create production lines that meet their requirements. Stainless steel machines, subjected to the right service, will remain operational for many years.