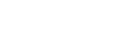

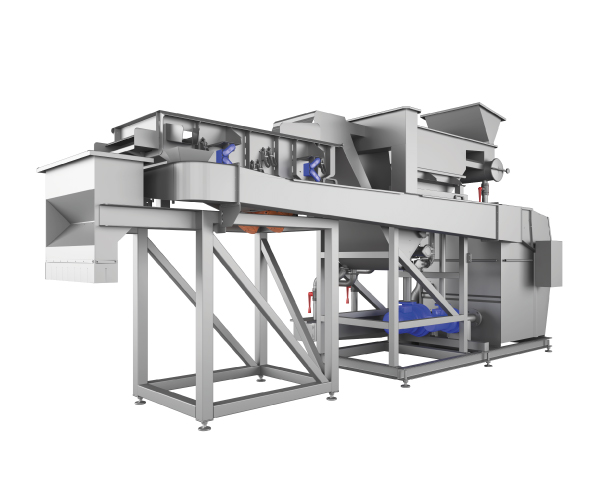

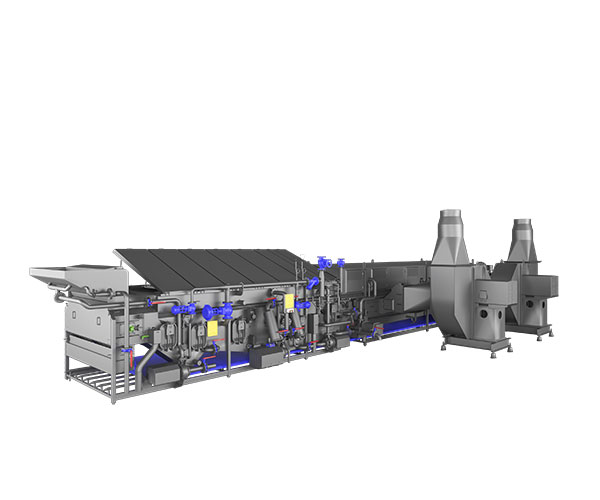

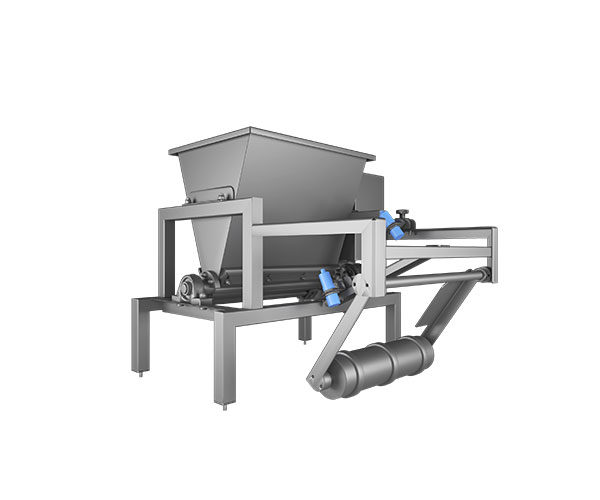

BARREL TIPPLER

The device is dedicated to emptying barrels during manual loading.

The barrel is transported with a forklift onto a roller conveyor, which is integrated with the machine. The barrel then moves to the tippler hopper, is lifted and pressed against the tippler cone.

After starting the machine, the tippler hopper tilts with the barrel and empties it. After emptying the barrel, the worker returns to the origins with the appropriate button on the control cabinet, and releases the pressure and protection devices.

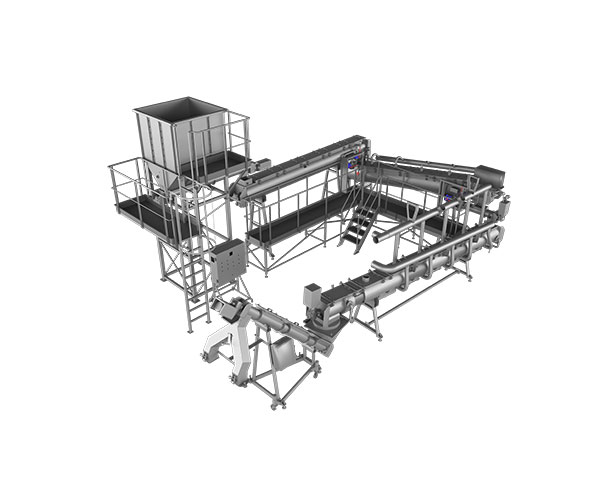

Efficiency – up to 15 cycles/h depending on the raw material, the type of packaging and the specifics of the task.

The machine is made of non-toxic, non-absorbent materials that are resistant to cleaning products and agents.