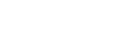

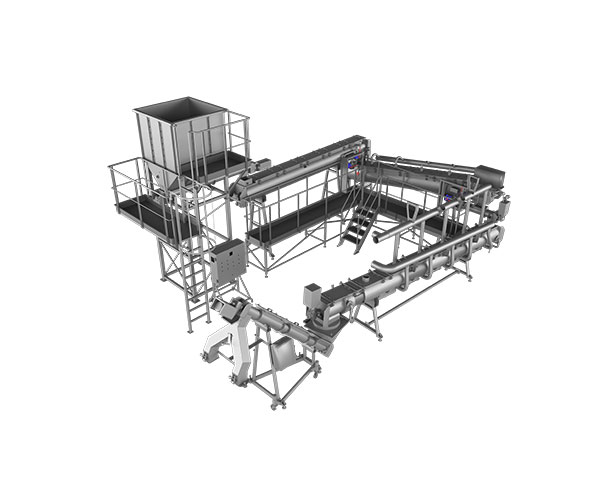

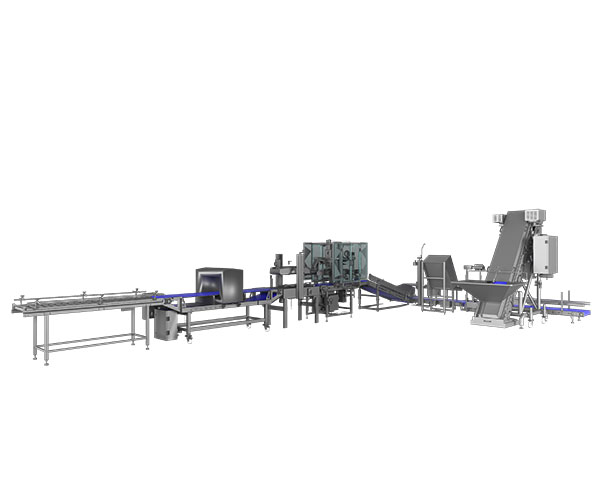

BAG AND CARTON PACKAGING LINE

Undoubtedly, the greatest advantage of this line is its versatility. The line can be adapted to two types of packaging, cartons and bags. Changing the packing mode is quick and easy.

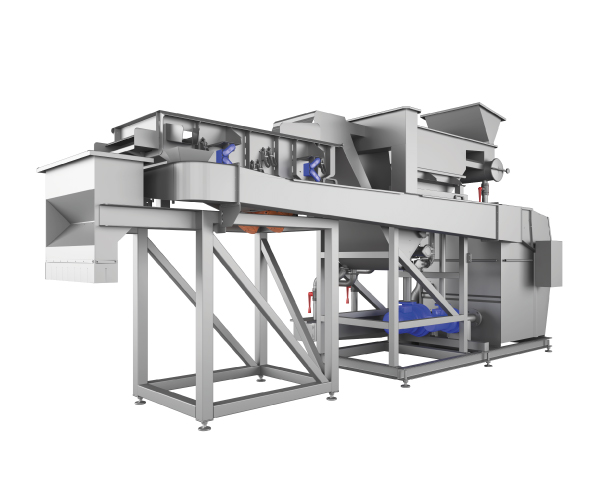

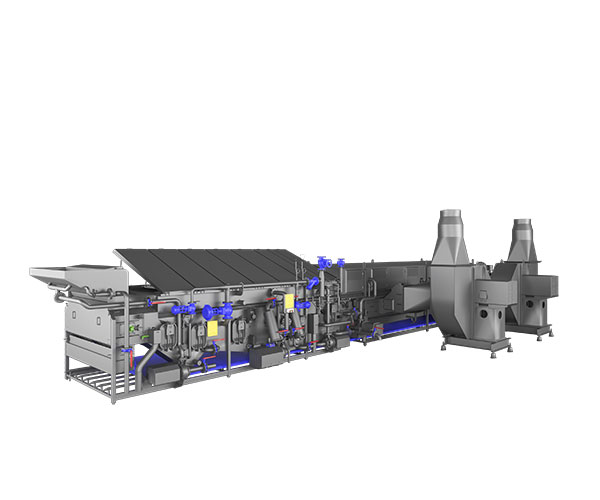

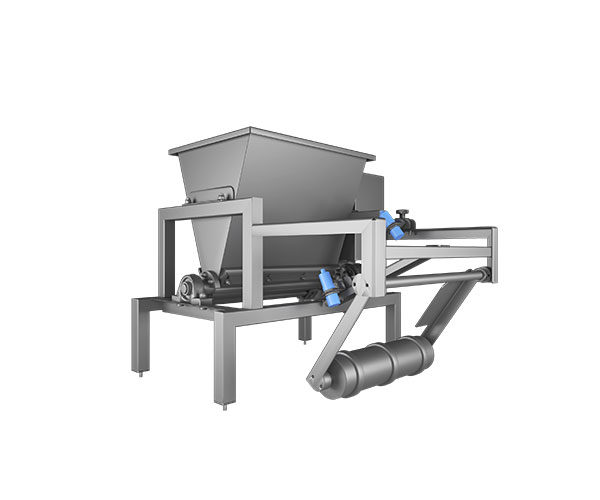

The packaging process begins with unfolding the carton and putting a plastic bag inside it. Next, the carton is placed under the batcher, which weighs in the appropriate amount of the product according to the prescribed procedure.

After weighing, the worker arranges the bag put inside, and the conveyor takes the carton to the next unit, which is the checkweigher. According to the set weight, there is a light signalling the correct weight or the need to add a product. You can add or subtract the product manually.

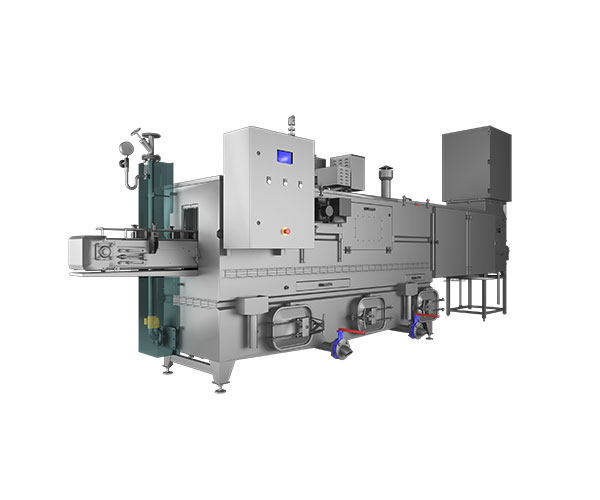

After confirming the correct weight, the carton is transported by the conveyor to the carton closing machine and then to the sealer. Everything is done automatically. These two machines are equipped with wheels, so it is possible to easily remove them from the line when packing the product into bags.

In the case of packing into bags, a stitcher or a sealer is located right behind the checkweigher, depending on the type of bag selected.

Then the product is transported by a conveyor to a metal detector, from where it goes to a roller conveyor serving as a buffer.