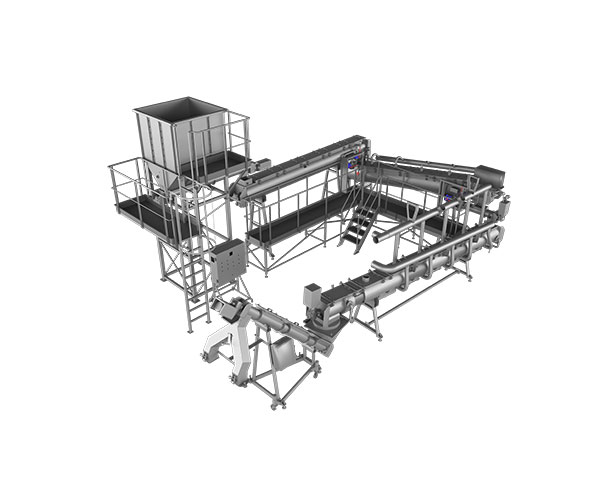

HERBS STERILIZATION LINE

The line is used for heat treatment of the product, in order to eliminate both vegetative and spore forms of microorganisms. It can be used for all kinds of herbs, grains, seeds, granules, dried vegetable flakes and other similar raw materials.

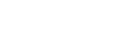

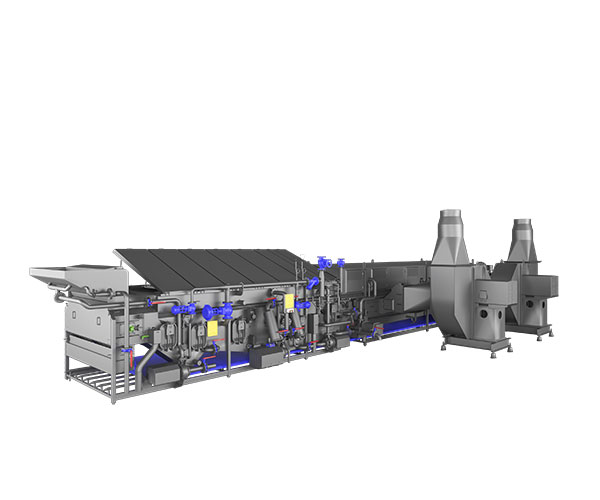

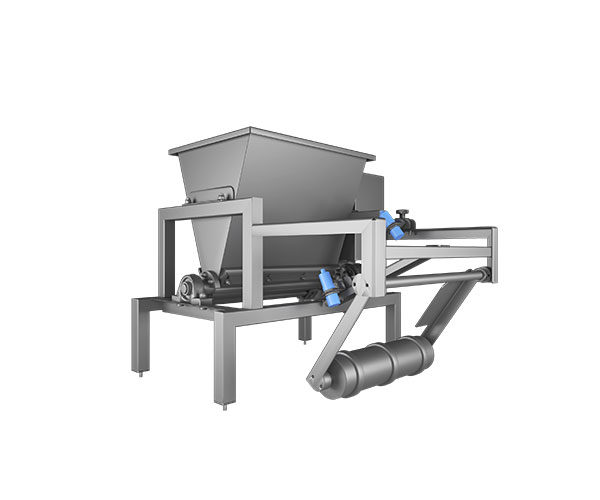

In the first part of the machine there is a receiving hopper. The product poured into it is collected by a screw conveyor to the next stages of the line. Thanks to the ability to adjust the speed of the screw conveyor, you can control its efficiency.

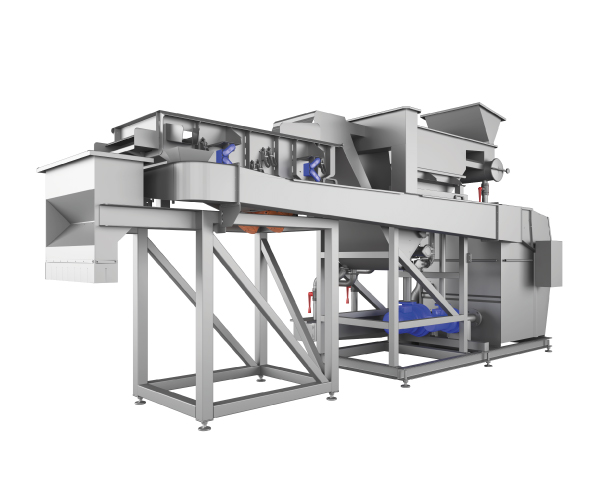

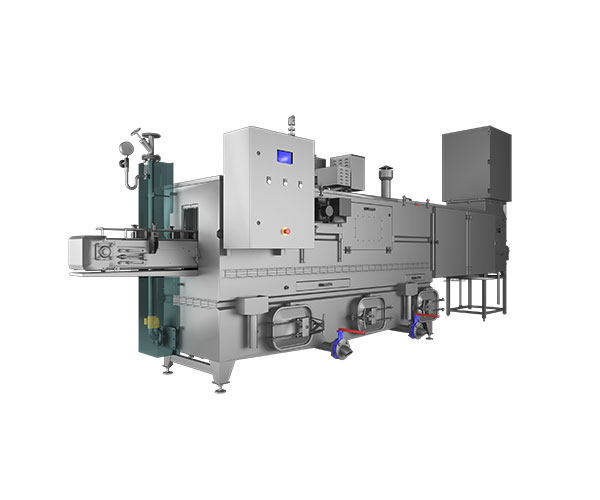

After that, the product is fed to the pre-heater. Thanks to that, it can stay in the sterilizer shorter, which impacts its final structure.

Then, the product goes to the main sterilizer where the sterilization process takes place.

After the sterilization process is completed, the product is cooled with air in a screw cooler. It is collected by a screw elevator with the function of easy bag-packaging.

- Thanks to the appropriate sterilization technology, the process does not cause the product to become wet.

- Capacity is up to 1 t/h, depending on the product.

- The second module contains devices that generate the media necessary to power the sterilization line, such as steam and chilled water.

Detailed refinement of this line resulted in a carefully thought-out concept of the technological process and transparent operation of the devices. Thanks to the cooperation with our clients, we can learn more about their needs and create production lines that meet their requirements. We can design all our machines according to individual customer requirements. Stainless steel machines, subjected to the right service, will remain operational for many years.

Benefits:

- Limiting the penetration of water vapor into the product

- Elimination of the formation of lumps and clumping

- Enabling the packaging of products immediately after the sterilization process, without the need to break up the lumps again

- The control system allows for supervision and control at any phase of the production cycle, and on each device separately

- Creation of reports and statements for a given batch

- Possibility of comprehensive line configuration