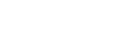

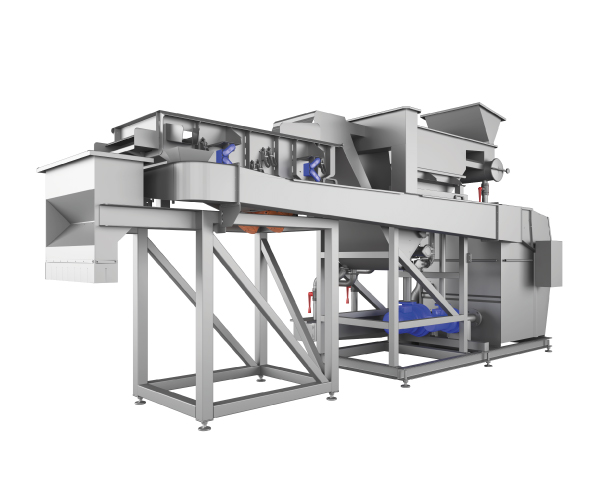

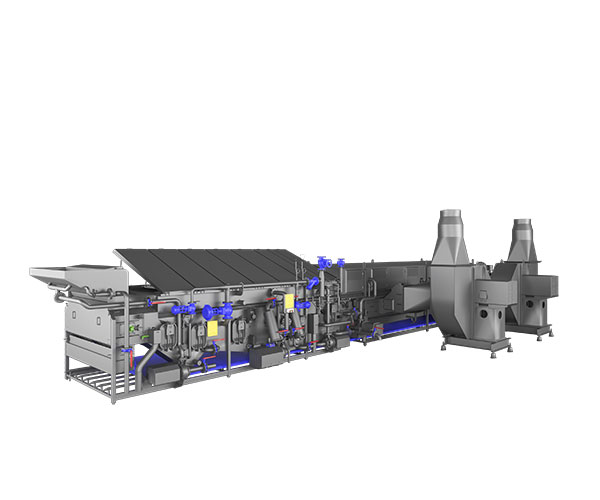

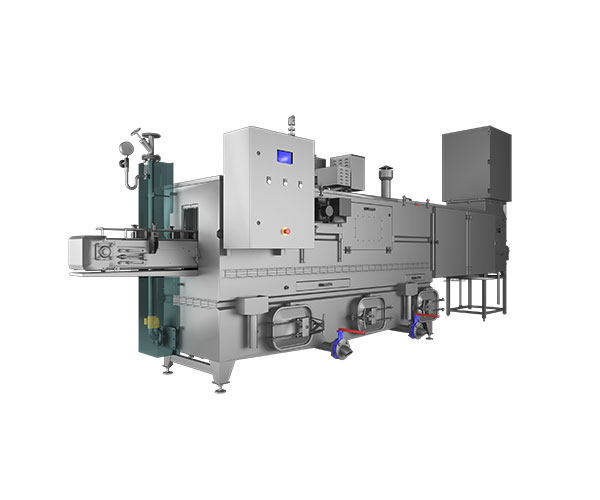

IMMERSED GLAZER

The product (deep-frozen) is thrown into the front part of the device – a tank filled with water. It falls on a conveyor belt built close to the water surface. The conveyor carries the raw material out of the tank. The negative temperature of the conveyor together with the water remaining on its surface create a layer of ice, which improves product’s appearance and protects it against damage.

Thanks to this variation of the glazer, you get a higher glaze yield and a heavier product. The machine is also equipped with a water pump ensuring constant internal circulation – connected lances provide an additional mixing effect.