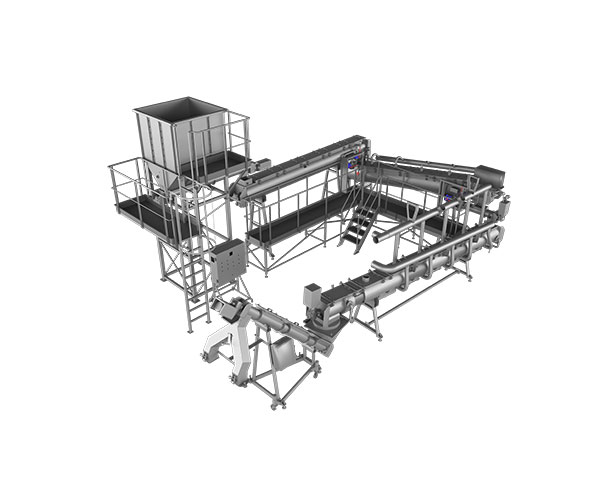

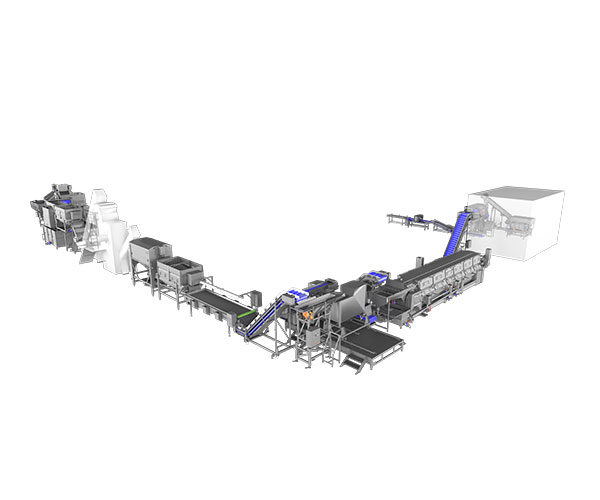

ROOT VEGETABLE LINE

A modern, customized line that enables the processing of root vegetables such as carrots, potatoes, beetroots, etc. into frozen cubes or slices.

All lines and machines produced by us are individually tailored to the customer’s needs.

The great advantage of the line is the ability to quickly change it from cubes to slices thanks to the wheel set.

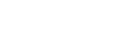

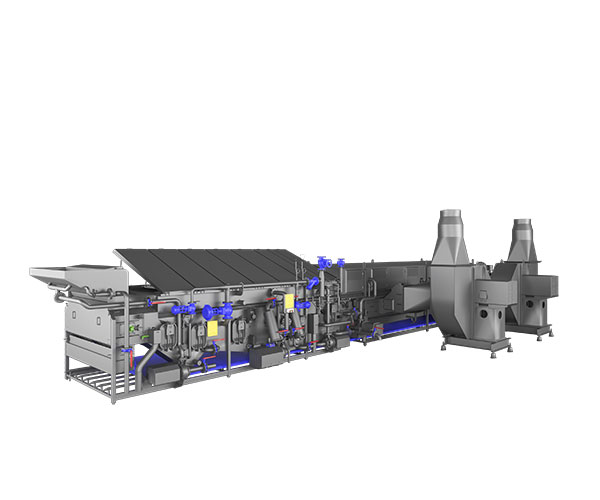

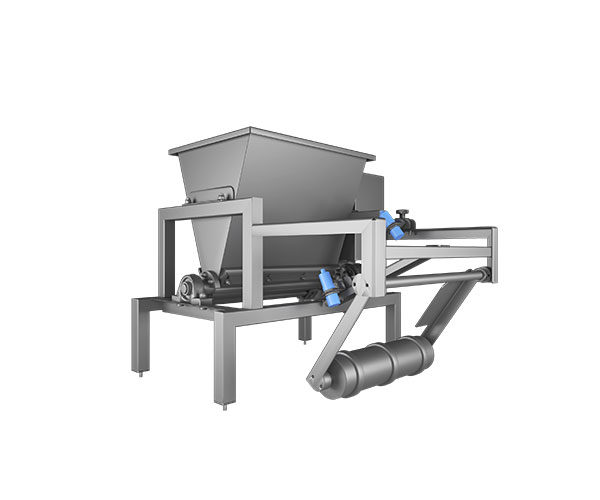

The process starts by feeding the vegetables onto the production line from the receiving hopper, which evenly distributes them. The product then passes through the drum soil remover. The soil removing takes place without water, which translates to the economic use of the machine and extended product life. Its task is to separate the product from the stones and initial washing of the soil.

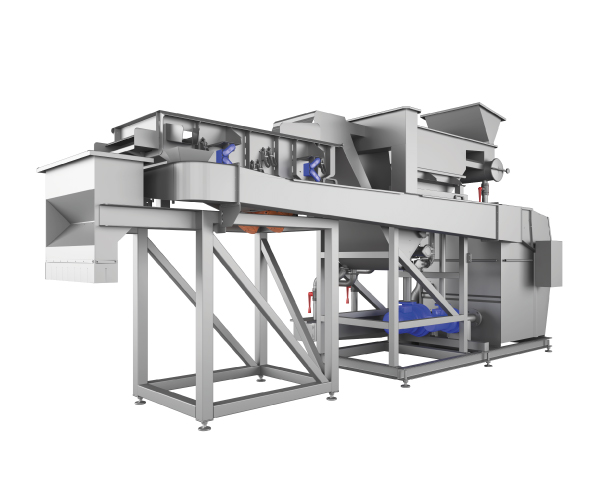

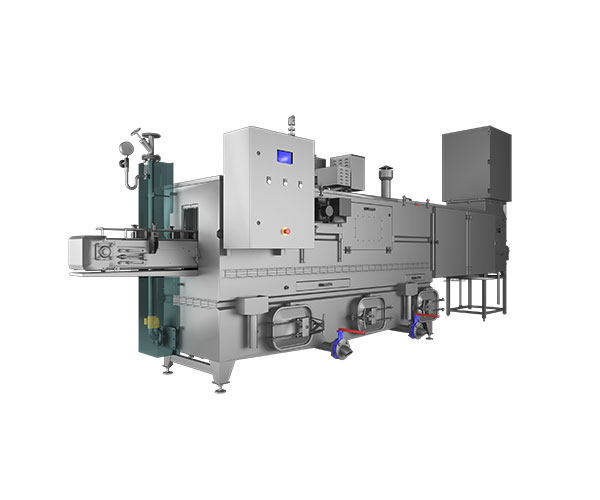

The product prepared in this way is transported to an immerse drum washer. During this process, the product is immersed in the water poured into the tank under the drum. The rotation of the drum mixes the raw material in the water bath, and the additional spray rinses away soil and other contaminants. Then, the washed vegetables are transported to the next stages of the line.

Depending on the customer’s preferences, we can complete the line with a steam blancher which will blanch the skin of the vegetable and prepare the product for its removal.

The polisher is the next stage of processing. At this stage, the product is peeled. After that, the vegetables should be washed again to remove the peel residues in an immerse drum washer.

Then, the product is transported onto an inspection conveyor, where the workers can make an additional visual inspection, and then to the conveyor feeding it into a slicer or a dicer.

The prepared product is transported to the blancher and then to the vibratory de-watering unit. This device is used to remove excess water from the product, before it is fed to the cooling tunnel. This allows for the freezing process to go more smoothly, which also increases the efficiency of the cooling tunnel itself.

Detailed refinement of this line resulted in a carefully thought-out concept of the technological process and transparent operation of the devices. Thanks to the cooperation with our clients, we can learn more about their needs and create production lines that meet their requirements. We can design all our machines according to individual customer requirements. Stainless steel machines, subjected to the right service, will remain operational for many years.